PROCESS CONTROL AND SAFETY SYSTEMS

Loops Automation has extensive experience in design and integration of integrated control and safety systems (ICSS) combining distributed control systems (DCS) or process control system (based on foundation fieldbus) with emergency shutdown systems (ESD) for oil& gas and power industries. Loops Automation analyzes the customer’s functional requirements and the subsequent critical selection of hardware devices and software packages to be integrated into the proposed total solution such integration is carried out all along the line in every phase of each job, including system and process engineering, design, selection, quality control and purchasing of products, hardware and software configuration, testing, installation, start-up, maintenance and spare parts, after-sales Service and training of customer personnel.

Distributed and Process Control System (DCS and PCS)

We design high available, distributed or single database open architecture plant control systems combiningadvanced diagnostics, redundancy, alarm managementand integration of third party controllers with multi serial and soft protocols(Ethernet, OPC, Profibus and MODBUS).We provide comprehensive technology skills and solutions based on industry recognized DCS and PCS systems such as honeywell (experionPKS), ABB (freelance and 800xA), schneider (plantstruxure PES), foxboro (T940), siemens PCS7 and emerson delta v.

Emergency Shutdown (ESD) and Fire & Gas Systems

We provide comprehensive technology skills and solutions for safety systems based on SIL 2 and 3 with various architectures including dual redundant (DMR, 1oo2D) and quadruple modular redundancy (QMR, 2oo4D).with a focus on ESD and F&G solutions that help customers meet plant, process and personnel safety requirements, Loops Automation combines leading brands in this field. We possess the design and implementation capabilities using the following ESD and F&G systems,honeywell FSC, HIMA, siemens S7-400F, ABB AC800M HI and allen bradley guardlogix.Loops Automation provides full design life cycle of safety instrumented systems (SIS) based on international standard IEC 61508 (functional safety of electrical/electronic/ programmable electronic safety related systems), carrying out and participating in studies for safety integrity level calculations, HAZOP and HAZID studies towards initial selection of ESD and F&G architecture and functionalities.Loops Automation carries out responsibility of complete integration of the DCS/PCS and ESD and F&G systems including all related interfaces in our workshop. This is normally verified during FAT (factory acceptance test) with client witness eliminating the need to have separate vendors for DCS/PCS and ESD systems.We offer plant control solutions for both offshore and onshore facilities including:

Field production facilities,degassing stations,NGL and natural gas processing plants,lube oil plants,boilers and steam generators,open cycle gas turbine power plants,compressor stations,pumping stations,bulk storage terminals and tank farms

Project Examples

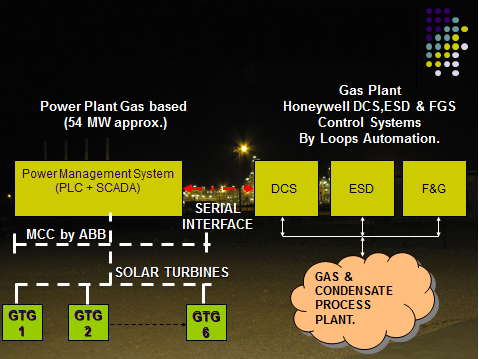

INSTALLATION AND COMMISSIONING OF PROCESS CONTROL AND SYSTEM

The project involves detail engineering installation and commissioning of DCS, ESD and F&G system for gas plant.Honeywell C300 controller and experion DCS.

SUPPLY, INSTALLATION AND COMMISSIONING OF PROCESS CONTROL AND SAFETY SYSTEM

Detailed design, panel engineering, general arrangements programming installation and commissioning

control system panels for field production facilities.

No comment