Power Automation

Loops Automation provides global customers with the most cost effective and tailored control system solutions, specialized in design, engineering and supply of complete turn-key Automation Solutions for power and utility industries covering generation, transmission and distribution systems.

Power Generation

• GTG (gas turbine generator) PLC-based unit control system

• Plant control system (DCS) for BOP equipment for open cycle gas turbine power plants

• Burner and boiler management systems for steam generators at thermal power plants

• Power management and monitoring systems (include intelligent load shedding and load sharing). This is mainly applicable at ARAMCO projects.

• Custody transfer flow metering and pressure reduction stations

Power Transmission & Distribution

• Substation automation for new and old stations (based on IEC 61850)

• AMR smart revenue metering for tie lines and main feeders (IEC 62056 DLMS)

• SCADA system, RTUs and gateways (IEC 60870-5-101, 104 and DNP3)

• Remote monitoring of protective relays (including remote download of DFR files)

• Integration of IEDs (intelligent electronic devices) and substation condition monitoring systems

• SOE (sequence of event) system

• Feeder automation (distribution automation)

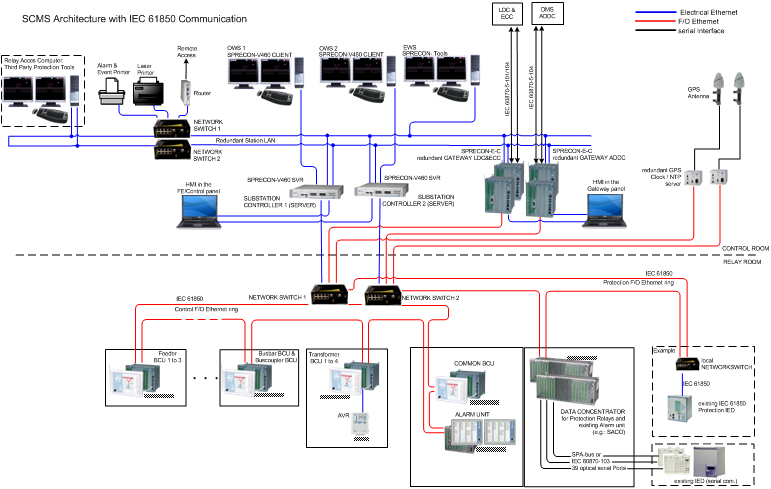

Substation Control & Monitoring System (SCMS) using IEC61850

Substation control and monitoring is essential in order to maintain an efficient and reliable electrical infrastructure. It provides the basis upon which various applications (within the substation and network) are built.It also forms the core for future SMART GRID applications within the transmission and distribution network.Substation automation systems using IEC61850 communication protocol have been developed to overcome the difficulties in proprietary systems. It involves many phases of integration. Horizontal integration between IEDs (intelligent electronic devices) at the bay level and vertical integration which involves collecting data from all substation IEDs (across the bays) and pass them to the station level (e.g. HMI),substation automation has a client/server architecture with peer-to-peer communications (via publisher/subscriber philosophy) between the IEDs.substation automation can be implemented in both old and new substations. It eliminates the requirement of large number of cables between bays and within. Logic is implemented in the bay controllers for both control and interlocking replacing the traditional relay logic and hard wiring.Loops Automation experience covers, design, implementation and commissioning of complete systems including IED parameterization (ICD files) and integration with NCC.

Project Examples

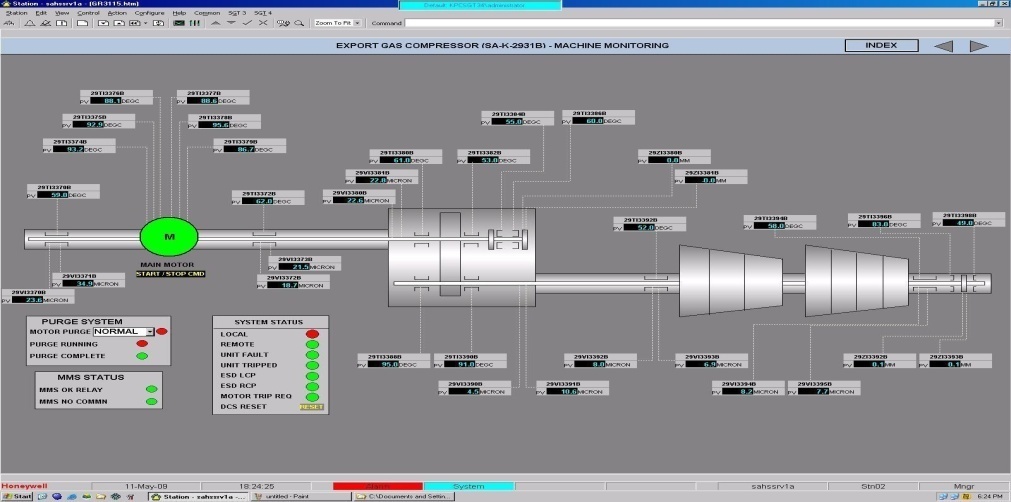

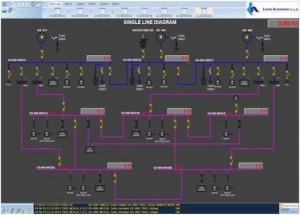

POWER DISTRIBUTION CONTROL SYSTEM FOR GAS PROCESSING PLANT

Project involves detail engineering and programming of plc & scada for the breaker control and power management system design, engineering, installation, training and maintenance tasks associated with all power production operations, Loops Automation helps you minimize risks and maximize uptime. We offer a broad range of integrated control and information solutions that are fully tested and field-proven to meet or exceed industry requirements. In addition, our globally available, on-demand services and support offerings provide a solid foundation for maximum uptime and availability.

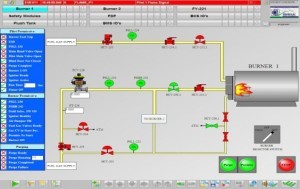

BURNER-1 HMI DESIGN

WinCC flexible the proven HMI software for flexible implementation in Burner management.In addition to advanced connectivity, WinCC offers such common HMI features as graphics, alarms, trends, recipe management, and security. Its advanced features include reporting, project cross referencing, process diagnostics, multiple language support, and complete redundancy.

No comment