Gas Flow Metering

Loops Automation is an independent system integrator for complete metering packages. You can count on us a reliable partner from concept engineering stage to commissioning stage with seamless support from our dedicated team of specialist engineers who have got many years of experience in similar field.

Dealing with transfer of ownership of gas and hydrocarbons, a small level of inaccuracy in integration can result in a significant loss of owner’s revenue. It is therefore Loops Automation is using ultra accurate integration of metering equipment to ensure that the accuracy of the transfer is technically proven which could not lead to the potential loss of client revenue from his land.

We provide total solution for custody transfer metering system for gas pipeline, truck loading and unloading, proving and sampling systems. As fully independent system integrators with continuous quest for world class quality, we ensure that we offer our clients a choice of best products and technologies. Our purpose of innovation is to create higher value for our customers. Not being connected to any particular manufacturers also allows us to fully comply with the right solution for the application meeting the right budget.

With more than a decade of experience in Custody transfer metering system, we have designed fabricated, integrated, installed and successfully commissioned hundreds of metering systems in the region. Our installed system consists of 2” to 16” Liquid metering skids, 8” to 32” Gas metering skids and various proving skids. We have used almost all proven technologies in Metering system which includes PD meters, Turbine Meters, Ultrasonic Meters, Orifice Meters, Coriolis Mass Flow meters etc.

We offer turn-key high end metering solution in accordance with customer specifications meeting International standards. We take single point responsibility from Front End Engineering and Design to site installation and commissioning.

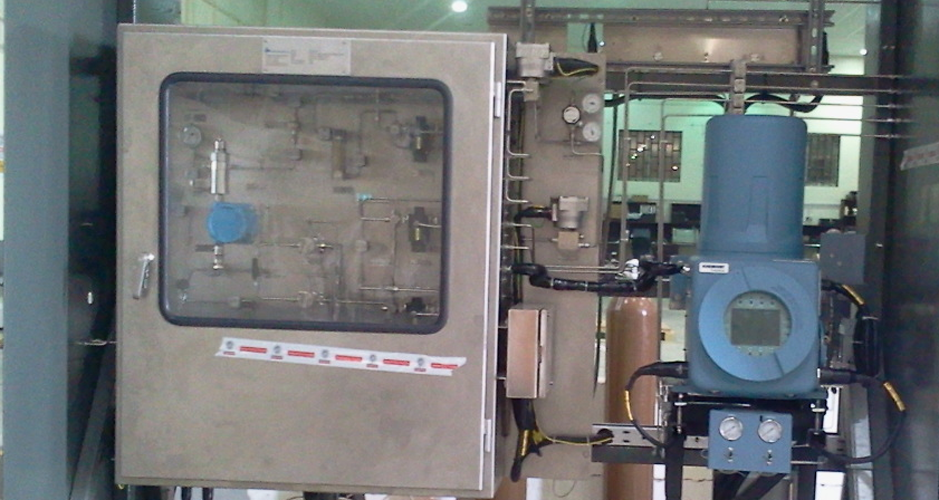

Gas Quality System

Gas chromatographs are commonly used for calculation of density on the basis of measurement of Gas composition. Certain Projects, use of densitometers for measurement of operating density helps for finding uncertainty.Gas Chromatographs are the responsibility of analytical Department. Loops Automation to provide necessary taps to provide streams to chromatographs. Supplier and Loops Automation interface with Project’s Analytical Department to insure necessary data is transmitted to flow computers.The Sampler to be operated in proportional to flow and an option to be provided for time-based sampling. In order to obtain a “representative sample”, the samples to be collected in proportion to the flow.Automatic samplers shall comply with the requirements of API MPMS Chapter 14.1.The sampler probe to be ANSI 316 stainless steel with 1/8 inch or ¼ inch diameter tubing and of the single tube or dual pitot tube configuration. For pipes up to 12 inch size, the probe tips to be located near the center of pipe and for pipe larger than to 12 inch in size, the probe tip to be at least 1/6th of the pipe internal diameter. Sample collection control systems shall provide an adjustable time based sampling rate. The sample rates or volumes to be unaffected by variances in pipeline or sample cylinder pressures or temperatures. Constant pressure sample cylinders to be used.

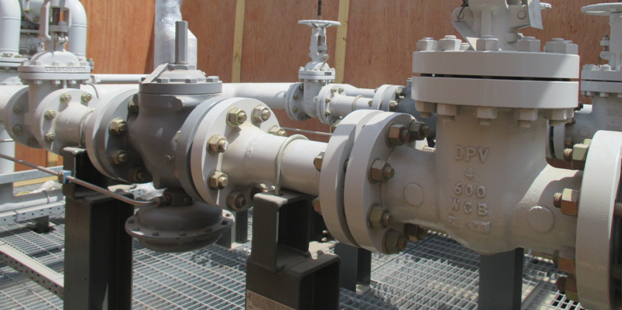

Pressure Reduction System

Loops Automation Providing Pressure Reducing & Slam Shut Valve arrangement Flow Control Pressure Reducing Valve with pilot Control arrangement.

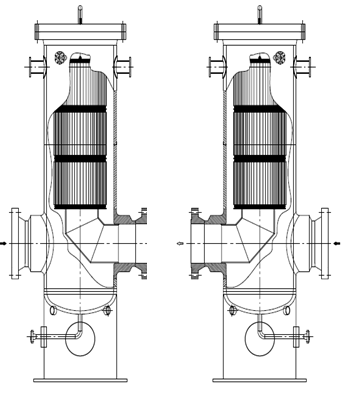

Filtration System

The filtration systems shall be skid mounted and shall be installed upstream of the meter skid. That will be redundant and of a type and size suitable for the application and the maximum design pressure.Filtration systems shall be specified by the Sub Vendor with advice from Loops Automation LLC. Filter Unit provide adequate cleaning of the gas without causing significant pressure drop.As a minimum, filtration system suitable for a minimum of 5 microns particle size with afiltration efficiency of 99%. Pressure drop shall be no more than 15 kPa /2 psi at the maximum design rate for the meter or group of meters.The design of the filter shall allow for online inspection and cleaning Without the need to remove it out of the line i.e., swing bolt, hinged-type closure. Differential pressure indicating switches shall be installed across the filters.

Project Examples

Dry Gas & Surplus Gas Custody Transfer Flow Metering Systems for NGL Plant

Design, engineering & supply of 22″ dry gas & 20″ surplus gas custody transfer flow metering skids with 16″ ultrasonic flow metering streams, on-line gas chromatograph analyzer & automatic sampling system.

Custody Transfer Flow Metering Skid for Gas processing Plant

Design, engineering & supply of dual stream ultrasonic gas flow metering skid (16″ class 600#) complete with gaschromatograph & automatic sampling system

Feed Gas Custody Transfer Flow Metering Systems for NGL Plant

Design, engineering & supply of 38″ & 32″ feed gas custody transfer flow metering skids with 16″ ultrasonic flow metering streams & on-line gas chromatograph analyzer.We provide total solution for custody transfer metering system for gas pipeline, proving and sampling systems. As fully independent system integrators with continuous quest for world class quality, we ensure that we offer our clients a choice of best products and technologies. Our purpose of innovation is to create higher value for our customers. Not being connected to any particular manufacturers also allows us to fully comply with the right solution for the application meeting the right budget.With more than a decade of experience in custody transfer metering system, we have designed fabricated, integrated, installed and successfully commissioned hundreds of metering systems in the region. Our installed system consists of 8” to 32” gas metering skids . We have used almost all proven technologies in metering system which includes PD meters, Turbine meters, ultrasonic meters, orifice meters.We offer turn-key high end metering solution in accordance with customer specifications meeting international standards. We take single point responsibility from front end engineering and design to site installation and commissioning.

No comment