Industrial Control & SCADA

Loops Automation provides global customers with solutions of the most cost effective and tailored turn-key control and monitoring systems using ranging from local operated PLCs and HMIs systems to remote operated RTUs and SCADA systems using the up-to-date advanced communications.

Loops Automation is proud to be an authorized system integrator to major automation OEMs and work closely with them to provide adequate and cost effective solutions for various projects.

Automation Equipment (PLC/HMI and PAC)

With a focus on automation solutions that help customers meet productivity objectives, Loops Automation combines leading brands in the field of industrial automation covering traditional programmable logic controllers (PLC) and more recently scalable, multi-disciplined and information-enabled process automation controllers (PAC). We possess the design implementation capabilities using the PLC systems from siemens, rockwell automation and schneider electric.

We offer PLC/HMI solutions for plant and unit control and monitoring applications including:

• Boiler and burner management systems

• Turbine control system

• Gas incinerator units

• Gas dehydration units

• Pumping stations

• Compressor stations

• MOV controllers at bulk storage terminals

• Metering control panel

Supervisory Control and Data Acquisition (SCADA)

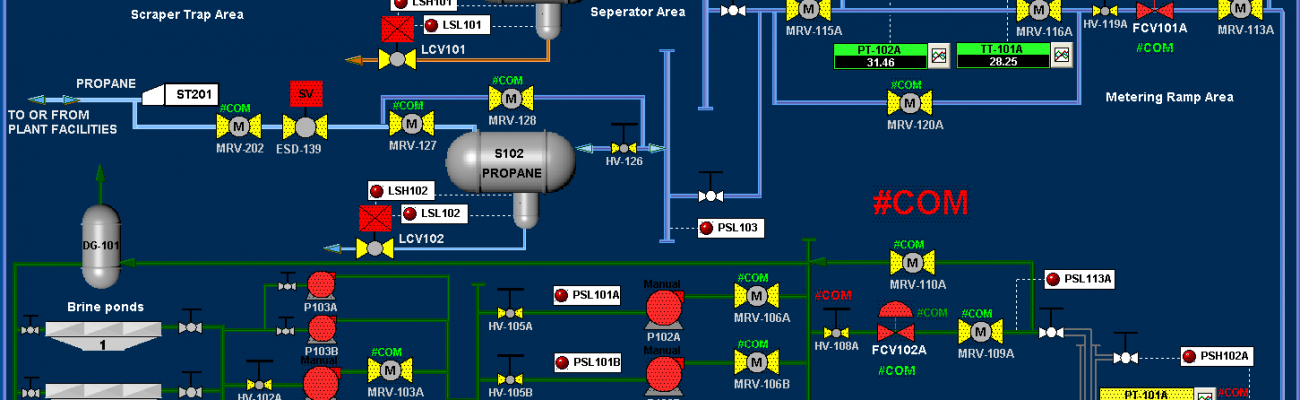

We offer implementation capabilities for the SCADA systems using cutting edge products composing of RTUs, SCADA software telecommunication solutions using GSM/GPRS, LAN/WAN, radio, microwave, wire line and fibre optic networks (SDH and PDH multiplexers). Based on application, specifications and project requirement; SCADA protocols are implemented using DNP3, IEC60870-5-101 (serial) and 104 (TCP) or MODBUS. We normally use various SCADA structures and software such as wonderware, ABB microscada, siemens wincc, vijeclitect and pcvue. SCADA systems are also used as the means for advanced SCADA applications such as pipeline leak detection and operation optimization. We offer SCADA solutions for applications including:

Gas distribution networks and control center, oil and gas pipelines, wellhead control and monitoring, CP (Cathodic Protection) test stations monitoring system, electrical substations and autorecloser control, utilities monitoring

Project Examples

SCADA FOR TEMPERATURE MONITORING

Redundant modicon PLC (Schneider Electric),VIJEO look as HMI, with maglis as front end user. Steam generation dept. Type of controllers redundant modicon PLCHMI/SCADA software Vijeo look / maglis as front end user no of I/Os 250 no of serial links 2 sets

NGL GAS DEHYDRATION PLC

MI/SCADA software monitor pro SCADA system.no of I/Os 230 all I/O signals were controlled using modbus plus network and modicon PLC (with redundancy) through monitor pro SCADA system.2 marshalling cabinets .The system include 230 I/O signals to be controlled using modbus plus network and modicon PLC (with redundancy) through monitor pro SCADA system. Logic and P&ID updated due to new modifications.

No comment