Loops Automation can provide comprehensive solutions for:

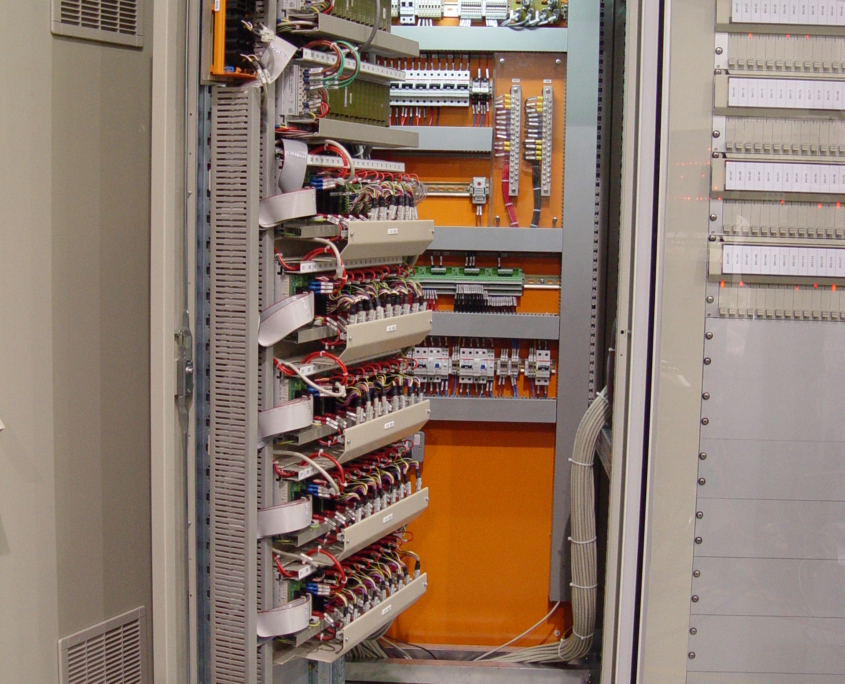

- Gas turbine generator and gas turbine compressor PLC-based unit control systems

- Plant control system (DCS) for BOP equipment for conventional power plants (simple cycle, combined cycle, and CHP).

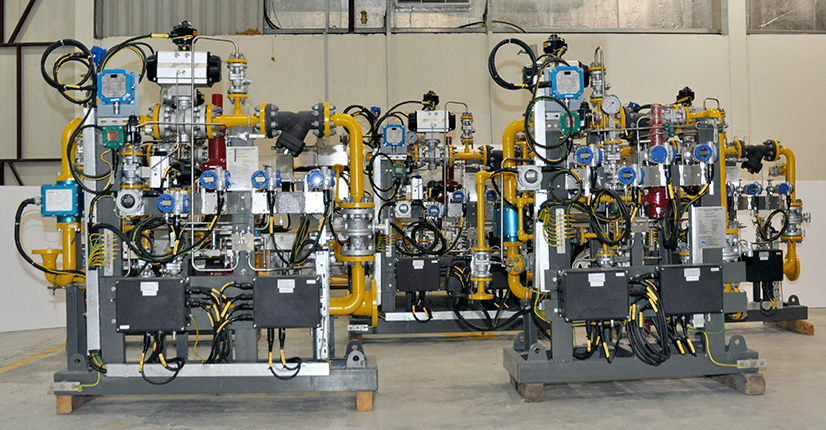

- Rehabilitation of instrumentation packages

- Mechanical rehabilitation

- Burner and boiler management systems for steam generators and furnaces at thermal power and industrial processing plants