With more than 25 years’ experience combined in metering instrumentation and control system engineering, our permanent engineers use research, process application calculations, and previous experience to select only the best flow meter or control systems. Loops Automation relies on the available tools and possesses thorough knowledge in flow metering and control system technology. “Your right measurement comes from our best measurement integration practice.” We value quality, safety, and customer service. Our team collectively has decades of experience supporting control systems of offshore oil and gas requirements for exploration and production operations.

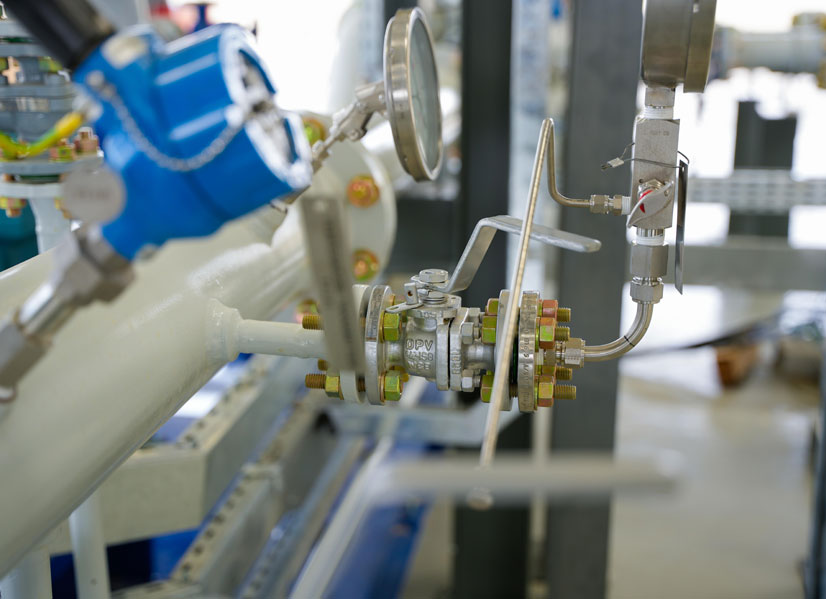

We offer turbo-machinery services and reverse engineering, fiscal, custody transfer, and allocation metering systems. Additionally, we offer loading, unloading, metering skids with top & bottom loading arm, and a skid mounted batch controller. Our projects span from ports and harbors to transportation of oil and gas.

Our client base is international and includes major and independent oil and gas, engineering, and chemical companies, electricity, water, port, and harbor authorities, as well as direct government authorities. Clients count on our team to provide high-quality turn-key services such as design, integration and measurement technology, systems, data telemetry, quality control, scientific analysis, and engineering or operational guidance. The team adheres to schedules and budgets, operates according to approved HSE protocols and quality standards, and always remains responsive to customer needs and inquiries.

Our Vision

At Loops Automation, our vision is to be the world’s leading provider of automation solutions for the oil and gas industry. Using the latest technologies and expertise, we aim to help our customers optimize their operations and improve efficiency, safety, and sustainability. We strive to work closely with our customers to understand their unique needs and challenges in order to develop tailored solutions that drive value for their businesses.

We will continue to invest in research and development to remain at the forefront of our industry, stay innovative, and improve our offerings. By realizing this vision, we will create a brighter future for our company, our customers, and the industry as a whole.

Our Mission

At Loops Automation, our mission is to provide our customers with comprehensive and reliable solutions that integrate their systems and processes. We are committed to delivering the highest quality services and products, as well as to tailoring solutions to meet the unique needs of each customer.

We strive to be a trusted partner for our customers and to work closely with them to understand their challenges and goals. By consistently delivering on our mission, we will help our customers achieve their objectives and forge a relationship based on loyalty and trust. Given our dedication to being a leader in our industry, we will continue to invest in our team, technologies, and capabilities to ensure that we are always able to deliver the best solutions for our customers.

Certifications

BY ALIGNING OUR BUSINESS PROCESSES WITH THE REQUIREMENTS SET OUT IN INTERNATIONAL STANDARDS, WE ARE ABLE TO ASSURE CUSTOMERS OF OUR ABILITY TO DELIVER UNRIVALLED LEVELS OF SERVICE AND PRODUCT QUALITY.

Quality and traceability are at the core of safe operations and are of paramount importance in our industries. Loops Automation adheres to internationally recognized standards and procedures, in addition to holding ISO certification appropriate to the business sector.

Great attention is paid to systems and procedures to ensure supreme quality. All of our employees undergo regular, formal training to ensure that they are fully up-to-date on the latest standards and legislation.

When you do business with Loops Automation, you can have full confidence that our products, systems, and procedures comply with all relevant international quality, health, and safety standards, backed up with rigorous record keeping and compliance procedures.

Our company holds the below listed certifications:

- ISO 9001:2015

- ISO 14001:2015

- ISO 45001:2018

All certification documents are available for review upon request.

Quality Policy

Our quality policy covers all activities that impact the service we offer to our customers and is fully embedded into our overall business management systems.

We are committed to be a leading provider in the field of:

“Engineering, Integration and Supply of –

- Industrial Automation & Control System for Power, Utility and Oil & Gas sectors.

- Skid Mounted Flow Metering and Instrumentation Packages for Oil & Gas sectors.”

In this endeavor, we will strive continually to comply with the applicable requirements and to review our continued suitability for:

To this end, our company recognizes the importance of providing clients with our expertise with budgetary consideration and time constraints.

HSE Policy

We are committed to be a leading provider in the field of:

“Engineering, Integration and Supply of-

- Industrial Automation & Control System for Power, Utility and Oil & Gas sectors.

- Skid Mounted Flow Metering and Instrumentation Packages for Oil & Gas sectors.”

We will protect the health and safety of our interested parties and avoid any adverse impact on the environment.

Employees and others acting on Loops’ behalf are responsible for knowing and complying with all applicable laws and regulations, related policies, standards, and guidelines.

The company aims to prevent accidents, near misses, and other disturbances in every task and operation.

Loops Automation is committed to:

- Complying with all relevant laws, regulations, and Loops policies.

- Operating and maintaining equipment, facilities, and processes in a safe manner.

- Responding to environmental, health, or safety concerns raised by our interested parties.

- Ensuring communication, consultation, and participation with interested parties regarding working conditions perceived to be unsafe or hazardous and, as appropriate, shutting down any operation deemed unsafe.

- Reducing the generation of waste materials.

- Setting, achieving, and working to continual improvement of targets through an action plan.

- Improving energy efficiency in existing operations and in new equipment and facilities.