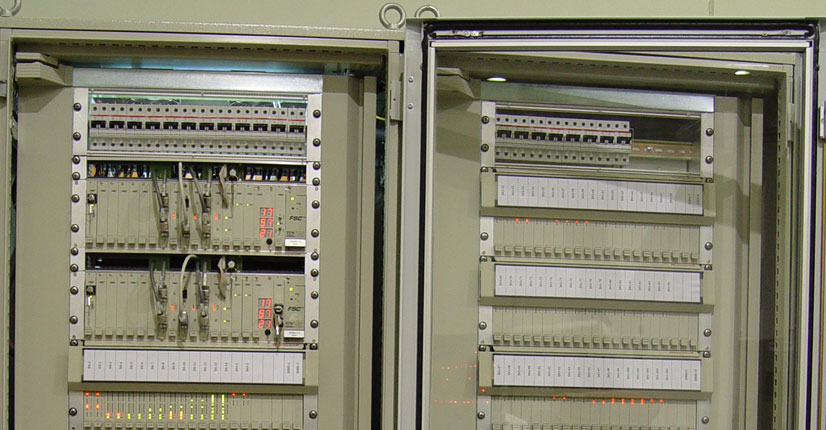

We provide comprehensive technology skills and solutions from leading industry brands for safety systems (ESD and F&G) in oil and gas processing plants. Our solutions are designed to meet SIL2/SIL3 Safety Integrity Level, with redundant architecture for high availability such as dual redundant (DMR, 1oo2D) and Quadruple Modular Redundancy (QMR, 2oo4D).

Loops Automation provides full design lifecycle of safety instrumented systems (SIS) based on international standard IEC 61508 (Functional Safety of Electrical/Electronic/ Programmable Electronic Safety Related Systems), carrying out and participating in studies for SIS calculations, HAZOP and HAZID studies towards initial selection of ESD, and F&G architecture and functionalities.

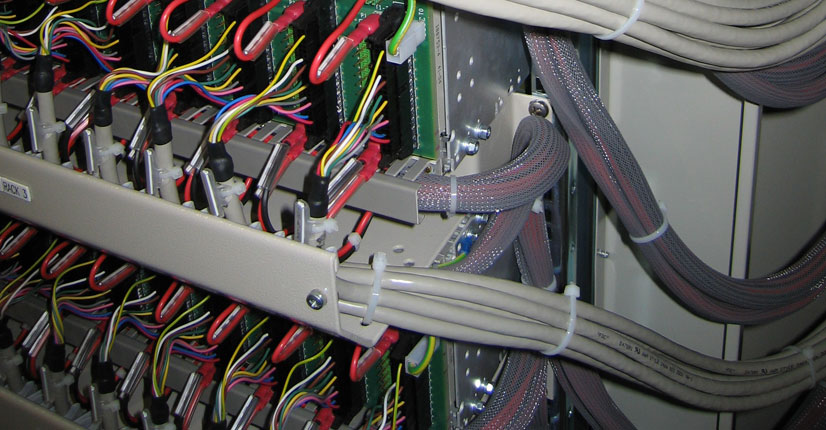

Loops Automation undertakes responsibility of complete integration of the DCS/PCS, ESD, and F&G systems, including all related interfaces in our workshop. This is normally verified during FAT (Factory Acceptance Test) with our client witness eliminating the need to have separate vendors for DCS/PCS and ESD systems.

We offer plant control solutions for both offshore and onshore facilities including:

- Field production facilities

- Central degassing stations

- NGL and natural gas processing plants

- Lube oil plants

- Boilers and steam generators

- Gas turbine power plants

- Compressor stations

- Pumping stations

- Bulk storage terminals and tank farms